|

Cold War Warriors The Silent Service during the Cold War - Part 4

Captain William Hicks, USN Ret.

Read Part 3

Collision in Rough Seas

USS Tullibee SSN 597 was a small ASW submarine with turbine electric propulsion. Tullibee had unique sonar systems including the first large ball sonar dome and a passive ranging sonar which required three domes mounted on the submarine deck (PUFFS).

Tullibee was not very fast and too small for adequate crew comforts with the crew size necessary to

accomplish the assigned missions. Only one ship of the class was built. On a Friday afternoon while Tullibee was at sea in a storm, a merchant ship reported a collision with an unseen object, possibly a submarine. The merchant was in the vicinity where Tullibee was assigned on the transit back to New London.

The USS Tullibee - note the three domes mounted on the her deck used for passive ranging sonar

The submarine force command structure activated the missing submarine planning and attempted to contact all submarines that were at sea. Ultimately, Tullibee made contact, reported that they were in a collision in very rough seas, they were still submerged, all systems were operating normally, and they intended to remain submerged to complete the

transit to the surfacing point off New London. With much relief, the CSS 2 staff and Submarine Base Port Services staff made plans to berth Tullibee when she arrived in port.

At about 10:00 pm, I was called at home and informed that Tullibee reported that when on the surface they determined there was a leak in the top of the forward ballast tanks and the forward Puffs (passive ranging sonar) dome was missing. Tullibee reported that they were able to keep water out of the ballast tank by continual de-ballasting with the

emergency diesel engine. So long as the diesel was running, the ship was stable on the surface. That changed all the plans.

The squadron commander directed that the submarine rescue ship USS Sunbird (ASR 15) get underway with the duty crew and whoever else they could get aboard on short notice and proceed to meet Tullibee. Tullibee and the Sunbird arrived in port without further challenges. Upon arrival early Saturday morning, the challenge was to patch the hole so that the

diesel could be shutdown with the ship stable on the surface.

The Submarine Rescue Vessel (ASR) USS Sunbird ASR-15. Submariners

referred to ASRs as “mother-pleasers” because they were incapable of rescuing sailors due to the depth of water nuclear submarines operated in, but mothers of submariners didn’t know this, so they slept better thinking their sons could be saved.

(Editor's Note - My father severed on the Sunbird)

The Submarine Base Repair Department formed and installed a temporary patch and the ship was stable. Notably, a week or so later, we were informed that when the merchant was inspected in Baltimore, a sonar dome was found in the hull. Reconstruction indicated that the results could have been much worse for Tullibee had the officer of the deck not taken

immediate and correct emergency actions when he spotted the merchant coming through the wave that was obstructing his view.

Once the ballast tank was patched, it was possible for Tullibee to return to service without the PUFFS system. Ultimately, a new PUFFS dome was obtained and installed. It was just another weekend for the squadron engineer and the entire squadron staff.

Maintenance of Nuclear Submarines

Maintenance of the first group of nuclear submarines in Submarine Squadron 2 was extremely challenging for a number of reasons:

- Designers of the initial group of nuclear submarines concentrated on "stuffing" a nuclear reactor and steam propulsion plant into a submarine hull. As a result, accessibility to individual components that would facilitate maintenance was not a primary consideration.

- Significantly greater amounts of seawater were required within the hull of a nuclear submarine during submerged operations. The design of the seawater systems including the ability to isolate sections and minimize the piping lengths and vulnerability of adjacent equipment was not considered as carefully as would be required in later submarine

designs. Low pressure, fresh water cooling systems were not employed in the initial submarine designs.

- Ship systems such as hydraulic and high pressure air were much larger and operated at much higher pressures than found in diesel submarines although in many cases, this was not adequately considered in selection of materials and installation.

- New technologies were necessary to support the increased range and submerged endurance of the nuclear submarine such as inertial navigators, oxygen generators, atmosphere-control equipment, and advanced sensors. Many of the technologies had not been previously packaged and applied in the manner to function on a nuclear submarine. Their reliability

and maintenance was a challenge.

- Maintenance procedures including rigging and removal instructions were not developed for the initial group of nuclear submarines and thus in some cases, these tasks were not evaluated prior to first use by the fleet at which time it was usually too late for design changes

- The one-of-a-kind nature of the initial nuclear submarines provided for limited experience in conduct of maintenance. It also resulted in many repair parts and replacement components being difficult to obtain.

- Routine preventative maintenance programs were not developed or were inadequate for many of the one of a kind or unique, small class submarines.

- High operational tempo frequently resulted in the early submarines requiring a significant amount of corrective and preventative maintenance which exceeded the capacity of ships force and the IMA during the port periods. As a result, the maintenance backlog increased and ship reliability was jeopardized.

One of the most significant improvements as the design and construction of nuclear submarines matured during my career was the improvements in the reliability of the systems and components and the ability to conduct maintenance when it was required. As a result, the reliability and the operational availability of ships of the submarine force improved

significantly from 1962 until 1990.

1973 Arab-Israeli War-expecting the unexpected

On the night of October 24, 1973, during the 1973 Arab-Israeli war I was called at home with the report that the U.S. defense condition had just been increased to DEFCON 3 and that we would be required to prepare several submarines to deploy on short notice. In addition, there was a Ballistic Missile Submarine (SSBN) in port on modified alert status

that we were required to get underway as soon as possible.

The SSBN was in port for maintenance during her deployment cycle. The material condition of the SSBN was less than optimum and a significant amount of maintenance was in progress. The scramble to get everything back together and to work around those items that could not be fixed was a significant challenge for a day or so, but ultimately, we were

successful in getting her underway. I did not go home for a couple days while the defense readiness condition was increased. We were successful in getting our other units in the necessary condition of readiness should they be tasked. However, the crisis passed and we returned to business as usual. The SSBN returned to port and the maintenance continued. The lesson is that the

unexpected can happen without warning, so be flexible and be ready.

The Zumwalt era and race relations

During my tour as squadron engineer, the navy experienced a significant upheaval as a result of worsening race relations in the fleet. Race riots had occurred on several large ships. Tensions were high at some bases. While the submarine force did not experience much of the extreme tension, we participated in the actions to combat the inequality and

lack of racial sensitivity. The new Chief of Naval Operations, Admiral Elmo Zumwalt mandated a number of new initiatives that rocked the establishment and challenged the established chain of command. He eliminated the enlisted, traditional, "white hat" uniform. He sent us all to racial sensitivity training—"Upwards" which was enlightening and a bit demeaning. We survived and

continued to get ships underway on schedule. The background for this chaotic situation is beyond my career and I will not try to discuss it. Suffice it to say that it was a watershed period for the U.S. Navy.

Orders to USS Philadelphia (SSN 690)

My tour as squadron engineer was extended from two years to three, either because there was no qualified relief available, or because I was a slow learner! I guess I ultimately got it right such that I received orders back to new construction and reported in October 1974 as the Prospective Executive Officer (PXO) of the pre-commissioning crew for USS

Philadelphia (SSN 690). Philadelphia was being built at the Electric Boat Shipyard in Groton, CT. so we did not have to move but my commute became a mile longer. This was my second tour at Electric Boat and my third tour in the shipyard—two new construction and one overhaul. Unfortunately my reputation for shipyard success only meant more opportunity to go to the shipyard.

The Electric Boat Shipyard in Groton, Ct. One of two remaining shipyards in

the US capable of building nuclear submarines. Click on photo for a higher resolution view.

Back to the shipyard again

The USS Philadelphia was the second ship of a new class of nuclear submarines. The first ship of the class, USS Los Angeles SSN 688 was being built in Newport News Shipyard in Virginia. Philadelphia was the first of the class to be built at Electric Boat in Groton. The growing pains of being the first of the class would be significant, frustrating,

challenging, and enlightening. The Los Angeles Class (688 Class) was a totally new design with larger hull diameter, more shallow test depth, greater speed, and a new design nuclear propulsion plant.

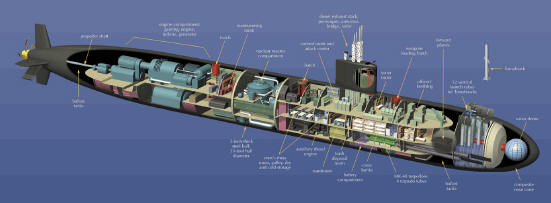

Los Angeles Class 688 - Click on photo for a higher resolution view.

The ships navigation, fire control, and sensor systems were greatly improved. They were all digital with an integrated central computer concept that was both an advantage and a challenge. The central computers were built and tested to military specifications which meant they would withstand lot2s of abuse in a warship environment, but the development

cycle was long. They were designed to meet the mil specs that they were several generations behind the state of the art when installed. They fell even further behind as time progressed. This situation drove a critical decision for future submarine designs to use commercial-off-the-shelf (COTS) digital equipment to gain the benefits of the rapid development cycle and rapid

improvements in digital computers and digital systems.

As had been the case with Sunfish, the function of the pre-commissioning crew was to train the crew to conduct the test program for the nuclear propulsion plant and to operate the ship on sea trials and beyond. Philadelphia was particularly challenging, since it was the first of a new submarine class upon which no crew members had previous experience.

While submarine and nuclear propulsion plant operations are similar between different nuclear submarine classes, the detailed procedures and the specific systems were different and required diligent retraining of every crew member. Only the Commanding Officer had any training on the nuclear propulsion plant that he received at Prospective Commanding Officer (PCO) training in

the offices of Admiral Rickover. For the rest of us, it was a matter of reading the Reactor Plant Manuals (RPM) and other training documents and lots of walk-through and talk-through practice. For ship control training, we had access to a simulator trainer in which the ship control team could practice and gain proficiency. Since no ship of the class had ever been to sea, the

accuracy of the ship control simulator had never been verified. In retrospect, it was adequate but there were a few surprises when we got to sea.

When the pre commissioning unit was formed, the ship was still on the building ways. Within a couple weeks, the ship was launched into the Thames River. The launching event was the occasion for a celebration sponsored by the shipyard in which the ship sponsor broke the traditional Champagne bottle on the bow and the ship slid into the water. Then there

was a party in which we saw Admiral Rickover in a totally different mode as a charming guest. My mother thought he was a very kind and thoughtful gentleman- not the persona that some of us had experienced, but one in which he was skilled when a good impression was required such as with wives and mothers or politicians.

Following the launching, we had to quickly complete initial qualification in order to support the shipyard schedule to conduct the initial filling and testing of the reactor piping systems. We had only a few weeks to meet this challenging schedule, but we made it. The initial pre-core, cold operations, as the test sequence was known, was completed with

few issues. The next sequence was pre-core, hot operations, which as the name implies, takes the systems hot to test flow rates and other operational design parameters prior to loading the nuclear fuel into the reactor. During this sequence of tests, several issues were identified that were basic design issues. Also during this period, the shipyard work force went on strike.

The shipyard management tried to keep the testing going with the non-striking, salaried staff. Part of the strategy, probably unspoken, was that ships force would do more to keep things moving forward. The crew tried to respond, but several "aw shucks" events convinced us that we needed to exercise significant care or we would get drawn into situations

that we were not qualified or competent to complete. Always a learning experience. The lack of the hourly workforce and the attendant inability to fix test issues slowly brought the efforts to continue testing in spite of the strike to a slow walk. The ship was falling farther behind schedule and our dream of commissioning on July 4, 1976 in Philadelphia with the President

and Queen of England in attendance was becoming the impossible dream. We never got around to inviting the President or the Queen.

The construction continued. Challenges regarding system construction and operability were a constant source of tension with the shipyard. Schedule slippage was also a thorn. When I was in Electric Boat during the construction of USS Dace, I was always amazed at how, when the shipyard got serious, they could produce. Senior management got involved, more

skilled workers were assigned, and things happened to meet or recover the schedule. On Philadelphia, I saw the same efforts and strategies by senior management, but never the same results. They simply were not able to respond in the same way. In large part, this was caused by the dramatic growth of the shipyard, many 688’s under construction, several new Ohio Class, Trident,

Ballistic Missile Submarines were under construction, and a lesser experience and I believe a lower, work ethic on the part of many of the hourly workers. A beer at lunch was more important than finishing an important critical-path, work action.

In part, this was a measure of the times and also a result of the acrimonious strike which had finally ended. There were also challenges with the construction documentation provided to the construction trades. The ship had been designed at Newport News where the manner in which construction details were placed on drawings was different from the

methodology at Electric Boat. As a result, the trades were not always sure where to find the details to complete a construction action. This situation resulted in significant rework and acrimony between the crew and the shipyard. It almost seemed that the attitude of the shipyard was that they built what was on the plans provided by the government from Newport News and if

that turned out to be a submarine- that was fine, but if it did not… that was not their fault. We built "what the plan called for" was often the response. In the end however, it usually turned out that they had not looked at all the plans. Once all the plans were studied, the issues were usually resolved. Just with delays and tension between the customer (us) and the

shipyard.

As with Sunfish, the culmination of the propulsion plant test program was Power Range Testing during which the critical reactor was exercised to the allowable limits and sometimes slightly beyond. The most memorable event was the power cycles when we cycled reactor power from 15% to 100% in 10 seconds or so. The dynamics of this new reactor were such

that it overshot the point at which increasing power-demand stopped. Thus we exceeded 100% power by a small amount. This event resulted in significant energy to find out why and identify who was responsible. I knew why, or at least that the same thing happened on Los Angeles at Newport News.

During the pretest review of the test procedure, I attempted to get the test procedures modified, but with no success. As it would happen, I was the Senior Supervisory Watch for the test which overshot 100%. At the critique, there was group amnesia by the Naval Reactors and Design agency experts as to the discussions regarding procedure changes and

thus it was the fault of my crew that we exceeded the allowable limits of the test procedure. I was not happy and said so. The solution was to expel me from the critique so cooler heads could identify the issue and assess responsibly. In the end it all became a footnote to the test program and the necessary changes were made to the procedures.

Keeping Admiral Rickover happy

Following successful completion of the test program, Sea Trials were next on the agenda. Again, Admiral Rickover would be aboard and in charge. As the Executive Officer, I had different responsibilities from the Sunfish Sea Trials. The first critical challenge was the sea trial letter that the Admiral would sign at sea during the trials. The text was

provided by his staff, but it was the responsibility of me and my yeoman to type and proof-read the several hundred copies and perfection was the only acceptable standard. Computer word processors were still in the future, but the Shipyard did provide an IBM electronic card reading typewriter so that if we got the letter correct once and embedded on the magnetic card, the

typewriter would produce identical copies (most of the time). Once I had a good copy, my proof reading became holding the one to be checked up to the light in front of the good one and verifying a match.

Frustrating, since I had so many other things to do as XO, but I understood my priorities. If Admiral Rickover was not happy, none of us would be happy. As always, many details were identified that were necessary to ensure Admiral Rickover was not irritated on the sea trials. The specified uniform items were procured; size small. The book list was

filled at a local book store. The special foods including seedless grapes were stocked. Rules of decorum were drilled into the entire crew. And, we got ready for the first trip to sea in a new ship. The sea trials actually proceeded reasonably well with only a few challenges such as maintaining depth and angle control while going backwards; a submerged condition for which the

ship was not designed. We did lose the anchor during the drop test. It was eventually recovered by divers and reinstalled. The weather was fine, so few got sea sick and we were able to transfer the Admiral off on schedule- a relief for all. Following the successful sea trials and final repairs, USS Philadelphia, SSN 690 was commissioned at Submarine Base New London on 25 June

1977, almost two years behind schedule, but ready for a successful career that would last for 34 years.

The USS Philadelphia “breaching” after a test of its emergency blow system.

The emergency blow system is designed to rapidly empty the sub’s ballast tanks

and in doing so, force the sub to the surface.

Read part 5 Read other articles by Captain William Hicks

Read other Cold War Warrior

Articles

|